Why do we want to see a “test print?”

If you have ever called us for service you will always be met with, “Send us a picture of your test print and we will get back to you.” What is a “test print” and why do we insist on seeing one before we continue?

If you have ever called us for service you will always be met with, “Send us a picture of your test print and we will get back to you.” What is a “test print” and why do we insist on seeing one before we continue?

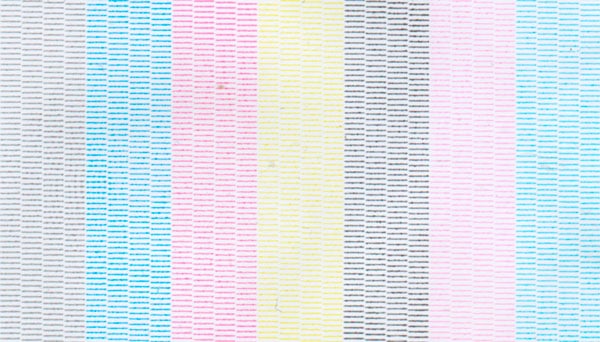

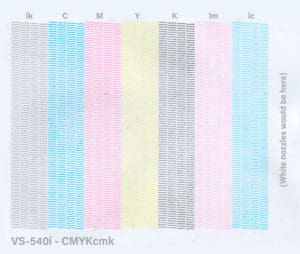

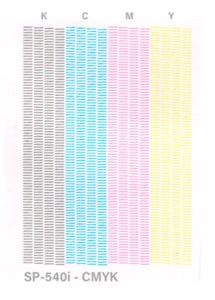

[NOTE: These are “perfect” test prints unless labeled with problems. The gray text and channel colors is for educational purposes – these do not print on your printer.]

First and foremost – what a “test print” is NOT. A test print is not a picture of your job showing…[fill in printing problem.] Often these pictures are not clear enough to see the problem and we have no idea what the file is supposed to look like anyway. A test print is not the “Test Print” in VersaWorks. This has the same problems as your job print. And – a real “test print” will show us what we really need to see.

First and foremost – what a “test print” is NOT. A test print is not a picture of your job showing…[fill in printing problem.] Often these pictures are not clear enough to see the problem and we have no idea what the file is supposed to look like anyway. A test print is not the “Test Print” in VersaWorks. This has the same problems as your job print. And – a real “test print” will show us what we really need to see.

The test print shows us the condition of the nozzles and much more. How do you print a test print? On most newer machines you use the FUNCTION button – FUNCTION-CLEANING-TEST PRINT-[ENTER]. It is that simple. Take a picture of that and send it off to us. [Some machines have a test print button on the control panel – press and hold it until it beeps.]

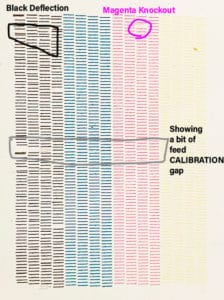

What do we see? We can see lost nozzle firings (knockout;) we can see crooked nozzle firings (deflection;) and we can also see some wavyness that may indicate an electronically spent head. We can also see if the feed calibration is tight or weak (not usually related to printing problems.)

In short, a test print usually shows us not only what the problem is, but what we need to suggest to correct the issue. Consider the “test print” the heartbeat of the machine.

The test print at the left shows the Magenta with one nozzle knockout and the black channel showing deflection. The Test print prints the head twice – so the gap inbetween the two printings is showing the feed calibration is a bit wide (where the knockout in the middle on the black is also showing.) This is a two head SP machine – and we can tell this from the test print as well.

The test print at the left shows the Magenta with one nozzle knockout and the black channel showing deflection. The Test print prints the head twice – so the gap inbetween the two printings is showing the feed calibration is a bit wide (where the knockout in the middle on the black is also showing.) This is a two head SP machine – and we can tell this from the test print as well.

If you regularly print a test print you will also see the condition of your machine. A test print that has dropout regularly can inform you that it may be time for a Preventive Maintenance [once a year] – and specifically time to replace the cap tops that help keep the ink filled into the heads. If you do have some dropout – a Normal Clean should show improvement each time. If there is a great deal of dropout you might try a Medium Clean. But be aware – a well tuned machine will not need any of this – so any cleanings you do are a stop gap until a technician can come in and tune the machine up.

As a last comment: the Powerful Clean is mostly useless for users unless a technician suggests it. Why? Because if the Normal & Medium don’t show improvement – the Powerful won’t as well – and it wastes ink and possibly does harm to the head. In short – don’t use it unless a tech suggests it.

Test Print – print regularly to see what a good test print looks like and to keep watch over your machine.